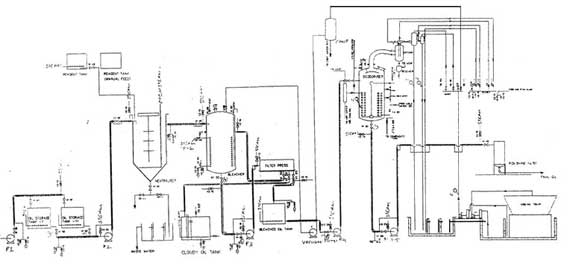

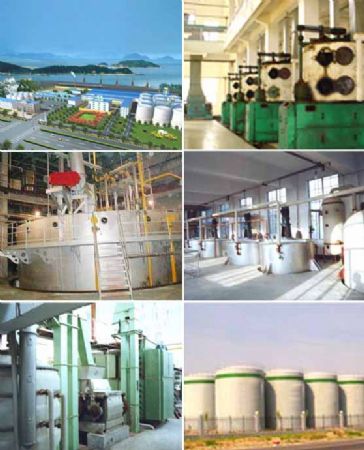

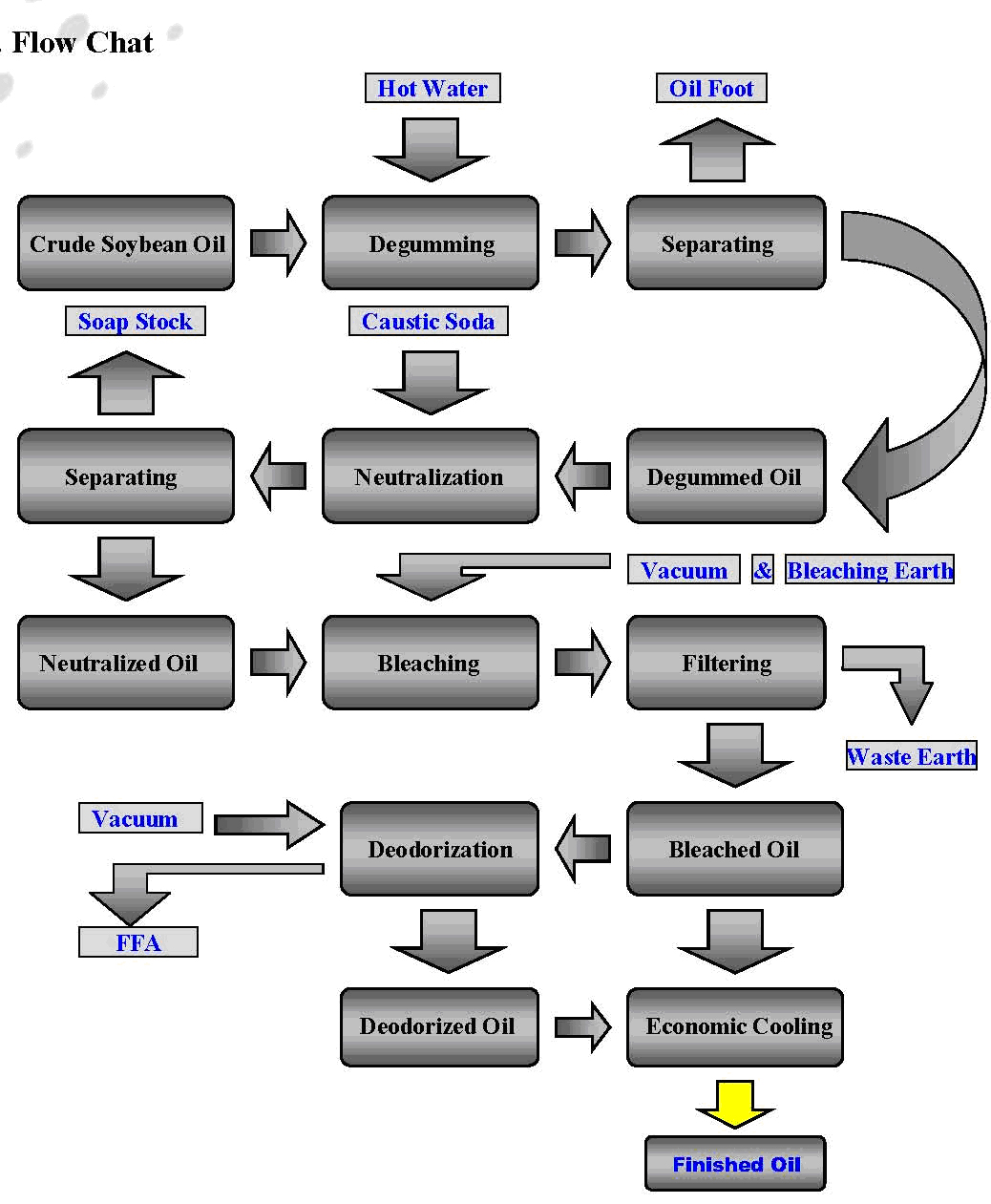

The oil refinery process involves the removal of impurities from crude vegetable oil to make it ideal for human consumption. The refinery process will vary based on whether the oil is going to be used as cooking oil or as fuel. Fuel refining is used to purify oil so it can be used as fuel while food refining purifies oil so it can be sued for cooking.

For cooking oil, the first thing you should do is to clean the seeds to remove dirt. Next, dry the feedstock because moisture can make the oil hard and cloudy, making it difficult to process. Once you have the oil with you, filter it with a sieve to separate it from the pulp.

An alkali is used in the oil refinery process to separate fatty acids from the phosphates. Next, centrifuge the oil to remove impurities. You can then wash the oils to remove soaps. You will need to bleach the oil to remove any coloring substances. Bleaching uses products such as acid activated clays which absorb the color pigments in the oil. Pace the clay in a filter paper and then pass the oil through it. The oil should be ready for human consumption.

In conclusion, Oil refinery process is important in making the vegetable oil safe for human consumption.